What are Class-X Capacitors

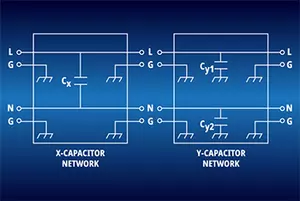

Commonly referred to as “line to line” or “across the line” capacitors, Class-X capacitors are used to minimize EMI/RFI that may be caused by differential mode noise in an AC power supply. Class-X capacitors are placed across the line and neutral connections to mitigate negative effects that may be caused by conducted interference, overvoltage surges, and voltage transients. But in order to provide a clean AC signal to the circuit they serve, Class-X capacitors are subject to all of the AC line variations which can create a hazardous situation if the voltage or power threshold of the capacitor’s capabilities are exceeded. In an over-stress situation, Class-X capacitors are designed to fail short-circuit, in order to trigger the circuit breaker or fuse to break the supply circuit. However, if the overcurrent protection devices are not fitted or fail to react, a Class-X capacitor presents a significant fire risk.

What are Class-Y Capacitors

Class-Y Capacitors are commonly referred to as “line to ground” or “line bypass” capacitors. Class-Y capacitors are typically placed in between the AC supply and ground, to handle EMI/RF noise caused by common mode noise. Class-Y capacitors are also subject to AC line variations via conducted interference, overvoltage’ surges and voltage transients, which can also lead to hazardous situations if the threshold of the capacitor’s capabilities are exceeded and the capacitor fails. Class-Y capacitors are designed to fail open-circuit which, different from Class-X capacitors, results in subjecting the circuit to an unfiltered AC power source. However, the risk of fire is reduced.

Safety Capacitor Classifications

As with many safety-critical devices, varying standards and respective classifications are used to indicate the capabilities and threshold of safety capacitors. There are a variety of standards that are used to define safety capacitors such as IEC 60384-14, UL 1414, UL 1283, CAN/CSA C22.2 No.1, and CAN/CSA 384-14. The most common standard IEC 60384-14 defines the safety classification of Class-X and Class-Y per various levels of Peak Voltage Pulse before failure.

Types of Class-X and Class-Y Capacitors

Class-X and Class-Y safety capacitors are used to filter AC signals and reduce EMI. To do so, however, they must be connected directly to the hazardous AC line voltage which requires that they be certified as “safety capacitors” to verify that they are safely operable under this condition. There are various form factors of safety capacitors that are used in safety-specific filtering circuits. Although not exclusively used as such, ceramic surface-mount and ceramic disc safety capacitors are commonly used for interference suppression AC line filtering applications while film capacitors are more often used for conducted emission attenuation.

Ceramic capacitors and film capacitors can both be used for either Class-X or Class-Y applications, but their form factors and individual characteristics may make one type more advantageous than the other in certain applications. Ceramic capacitors are more often used for antenna coupling, primary and secondary coupling such as switching power supplies, line disturbance suppression such as high-speed switching controls such as motor control, relays, switching power supplies, and inverters. Film capacitors are often used where their self-healing properties are advantageous such as capacitive power supplies, energy meters, automotive applications, and severe ambient condition environments.

Conclusion

Class-X and Class-Y capacitors are used to filter AC power line to reduce EMI and RFI in sensitive electronics applications. There are various classifications of both Class-X and Class-Y capacitors with different abilities to withstand varying levels of continuous AC, peak impulse voltages and voltage transients. Regardless of the application, safety capacitors are essential to providing power to signal-sensitive electronics while mitigating the risk of a fire or a shock hazard.